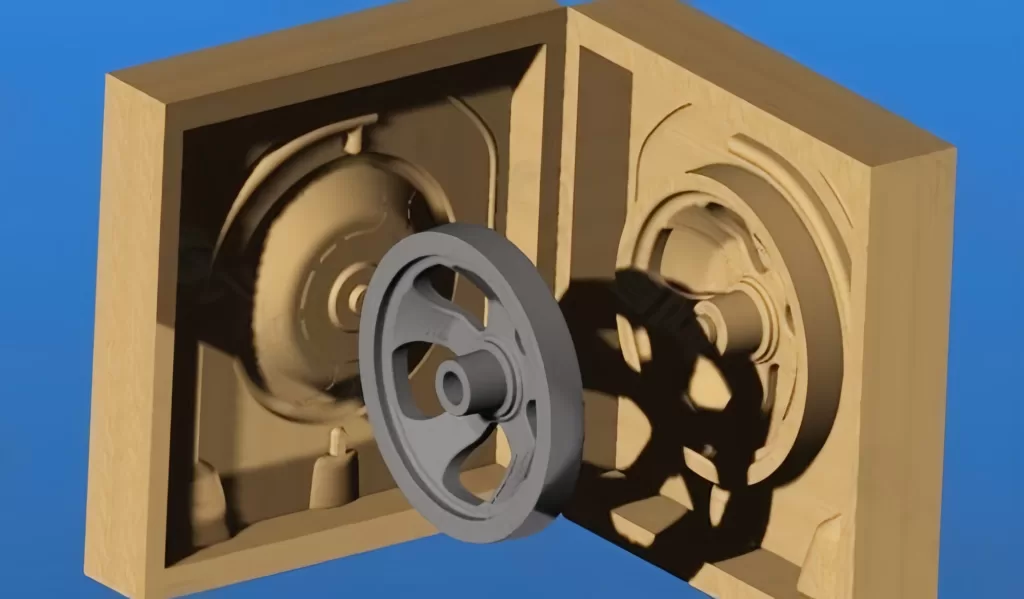

Casting – the process of melting metal, creating a mold, and pouring the molten metal into the mold to solidify and form a metal part blank with specific shape, size, and properties. Casting involves melting metal into a liquid that meets certain requirements and pouring it into a mold. After cooling and solidifying, followed by cleaning and finishing, the result is a cast piece with a predetermined shape, size, and properties. Casting blanks are almost near their final form, which minimizes the need for machining, reduces costs, and cuts down production time to some extent. Casting is one of the fundamental processes in the modern equipment manufacturing industry.

The step-by-step process of casting:

Liquid Metal → Filling the Mold → Solidification and Shrinkage → Casting Completion

Common Casting Techniques:

- Sand Casting: Utilizes sand-based molds and is known for its versatility and low-cost tooling.

- Die Casting: Uses high pressure to force molten metal into steel molds and is ideal for high-volume production of detailed parts.

- Investment Casting (Lost-Wax Casting): Known for high precision, it involves creating a wax model which is coated with refractory material to form a mold, then melted away.

- Permanent Mold Casting: Employs reusable molds, suitable for medium to high-volume production.

- Centrifugal Casting: A method where molten metal is poured into a rotating mold, producing cylindrical parts.

- Lost Foam Casting (Full Mold Casting): Similar to investment casting but uses a foam pattern which vaporizes when molten metal is poured in.

- Shell Mold Casting: Involves a shell-like mold made of sand and resin that creates finer finishes and tighter tolerances.

- Plaster Casting: Similar to sand casting but uses plaster for the mold material, providing a superior surface finish and detail.

Advantages of Casting:

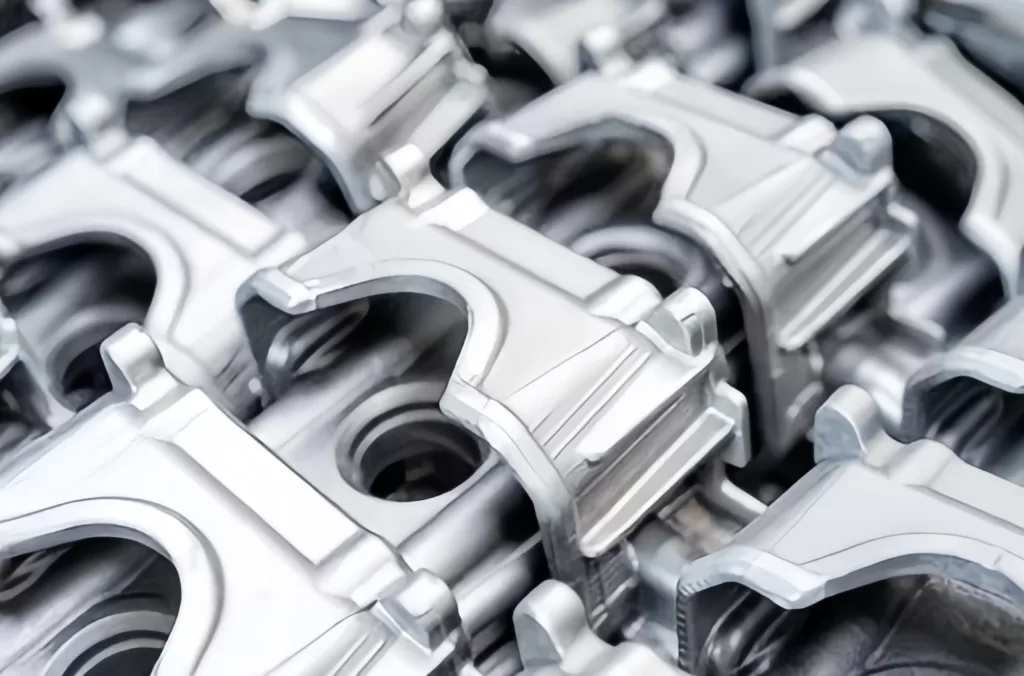

- The ability to create complex shapes and designs: It can produce a wide variety of shapes, from simple to highly complex geometries, including internal cavities and hollow sections.

- Cost-effectiveness for large production runs: It’s cost-effective for large quantities due to the reusable nature of molds. Suitable for mass production with consistent quality.

- Wide Range of Materials: Various metals and alloys can be cast, such as iron, steel, aluminum, bronze, and more.

- Minimal Waste: Excess material can often be melted and reused.

- Size Capability: Castings can range from a few grams to several tons.

Casting, while versatile and widely used, has several limitations:

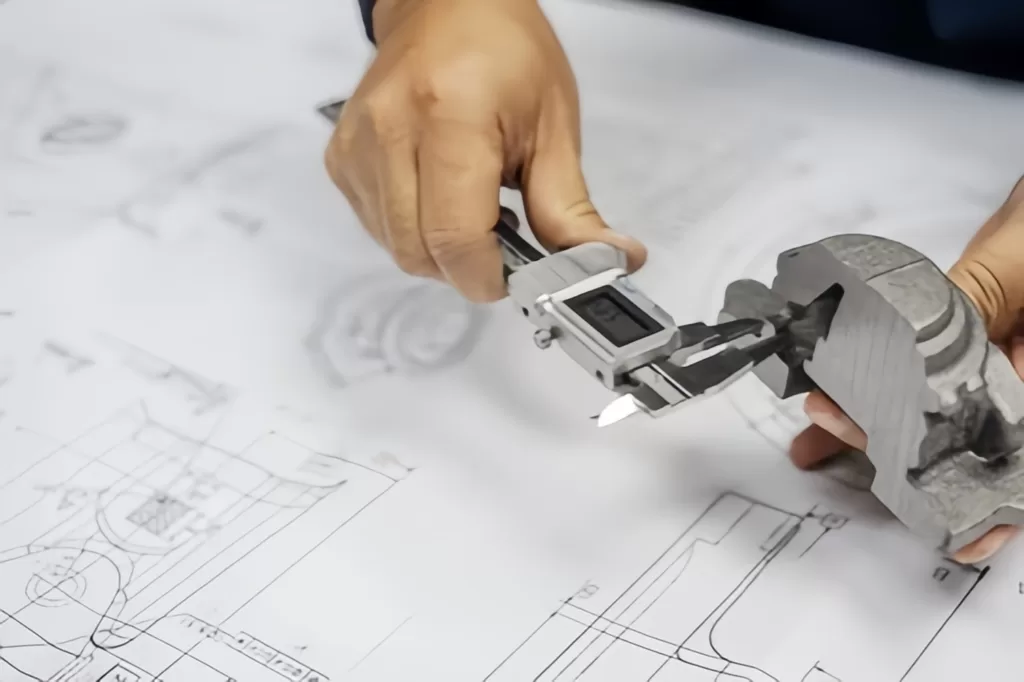

- Dimensional Accuracy: Castings generally have less dimensional accuracy compared to machined parts and may require secondary machining for precision features.

- Surface Finish: The quality of the surface finish in casting is often rougher than that achieved through other manufacturing processes.

- Material Limitations: Not all materials can be cast. Some may have high melting points or other properties that make them unsuitable for casting.

- Porosity: Cast metals can be porous, potentially leading to weaknesses in the final product.

- Complexity Costs: While casting can produce complex shapes, the more complex the shape, the more costly the mold design and production can be.

- Size Limitations: There are practical limits to the size of parts that can be cast, governed by the casting equipment and handling capacities.

Casting is a manufacturing process in which a liquid material, typically metal, is poured into a mold containing a hollow cavity of the desired shape and then allowed to solidify. The solidified part, known as a casting, is ejected or broken out of the mold to complete the process. This technique is used to create complex shapes that would be difficult or uneconomical to make by other methods. Casting is a versatile and ancient process dating back thousands of years, and it remains fundamental to modern manufacturing for its ability to produce detailed and robust components.